1. brief introduction

Thin film switch is a multilayer structure (plane) type button switch which is composed of insulating material layer with a certain elasticity. It integrates functions of buttons, indicator elements and instrument panels. The film switches only by the vertical elastic film spring, elastic film even after millions of times and creep, the creep rate is very small, only 0.1-0.3MM, and the rationality of material selection, so the film material can withstand more than one million life without deformation, these are determined by the durability film switch.

Membrane switch, beautiful appearance, long service life, simple structure, convenient installation and use, feel good, the advantages of small area, and is widely used in all walks of life, small household appliances to high-tech products, slowly replaced part of the touch switch market, occupies a great share in the market.

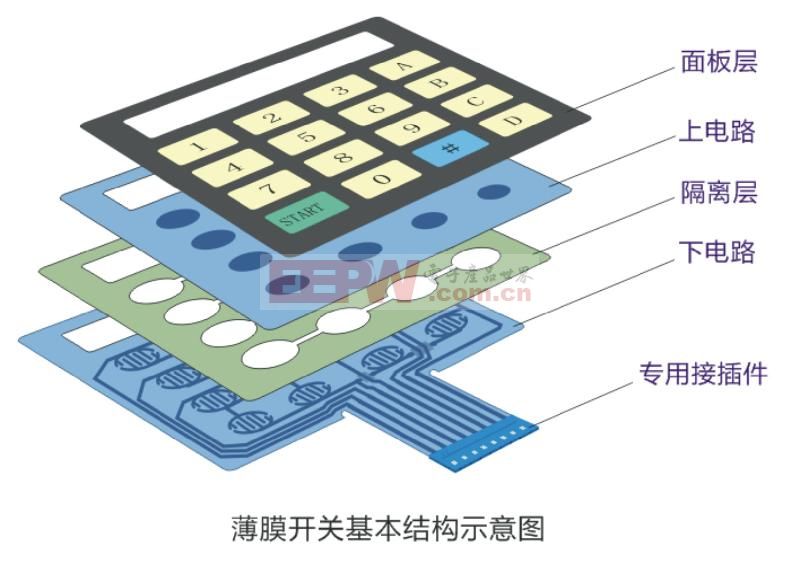

2. basic structure

Generally speaking, the common membrane switch is made up of 6 layers of materials. According to the order from table to interior, they are panels, surface gluing, upper circuit, isolation layer, bottom circuit and bottom glue. Each layer of structure is described below.

1) panel: the panel is the "outer garment" of the whole membrane switch. On the basis of arranging the key properly, it will play a necessary role in decorating the whole thin film switch by different colors, patterns and key shapes. The most important function of the panel is the marking and key action. Therefore, the material must be highly transparent, high ink adhesion, high elasticity and folding resistance.

2) the upper and lower circuits: the upper and lower circuits are the electrical components of the thin film switch, and also the "off" and "key" of the switches. Their performance directly affects the performance of the switchgear, mainly due to a conductive material printed on the film. The upper and lower circuits play the two electric shock roles that are necessary for the switch closure, the thickness of which is generally within 0.05--0.175MM, and the most common is the use of 0.125MM PET.

3) face glue, isolation layer, bottom glue: the material of these three layers is both double-sided adhesive. Because of the different position in the switch structure, there are different names. The three layers of double face glue have different thickness by their respective levels. This is mainly determined by the thickness of the switch and the operating force of the key.

3. working principle

Basic working principle is as follows: when the thin film switch panel is not pressed, thin film switch is in the normal state, the upper and lower contact is in off state, the isolation layer isolation effect on on line; when the panel is pressed, the contacts on the circuit and the lower line downward deformation, and the circuit is switched on, after conducting lines to the external connection of instrument (substrate) on signal, so as to realize the corresponding function; when the finger after the contact bounce back on the circuit, the circuit is disconnected, a signal trigger circuit.